-

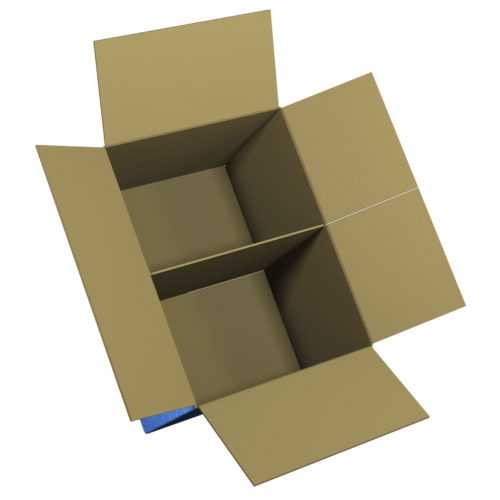

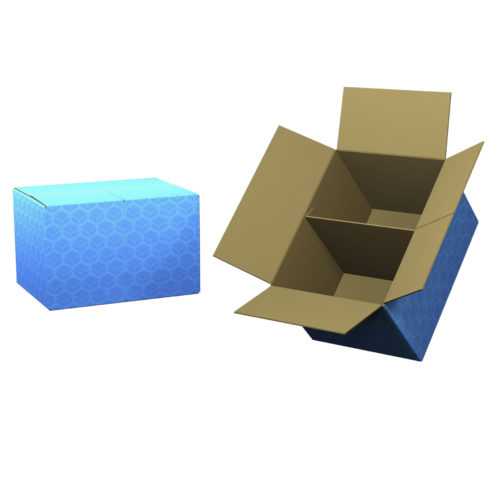

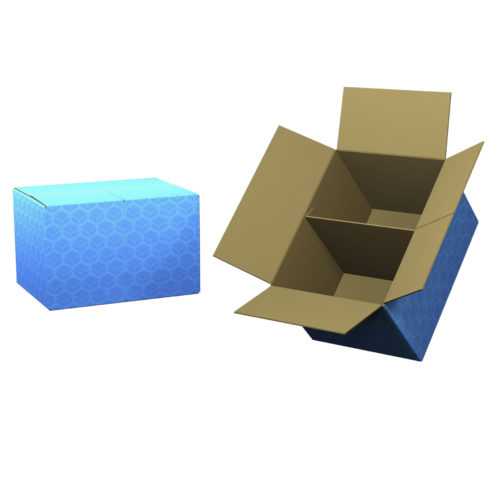

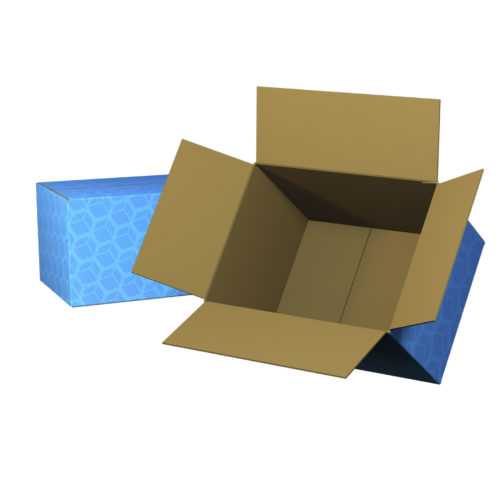

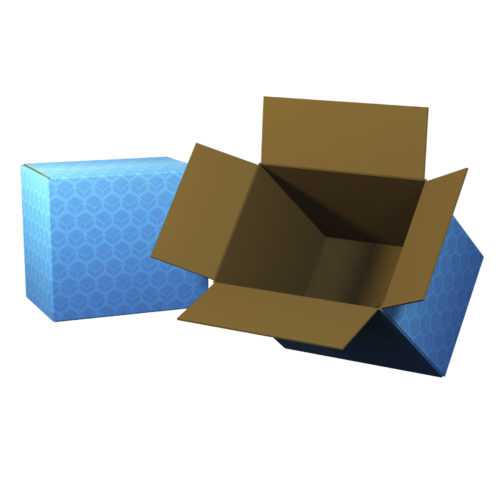

This Shipping Box With A Built-In Divider is a great tool to keep your products organized and safe during shipping. Thanks to the divider in the construction, your can have multiple product types segmented inside the box. Or you could create a great presentation inside using the different open areas around the divider.

This Shipping Box With A Built-In Divider is a great tool to keep your products organized and safe during shipping. Thanks to the divider in the construction, your can have multiple product types segmented inside the box. Or you could create a great presentation inside using the different open areas around the divider. -

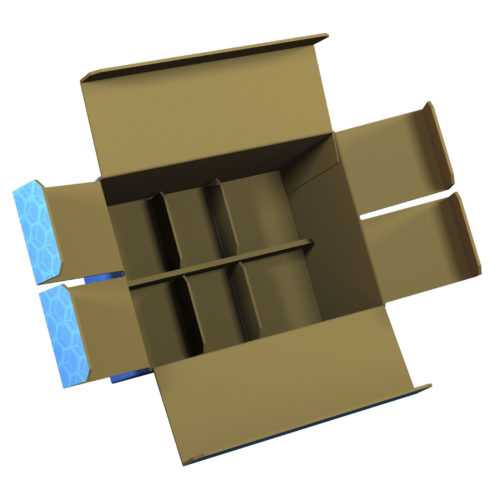

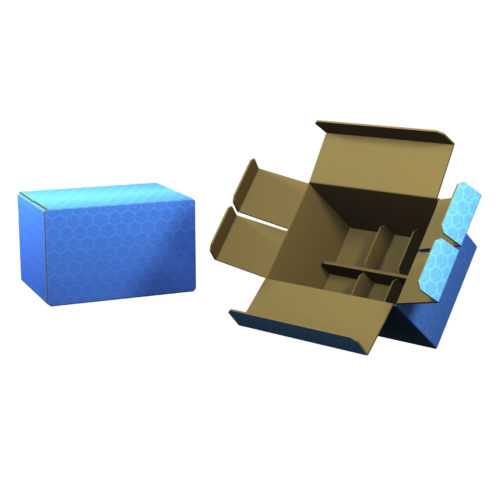

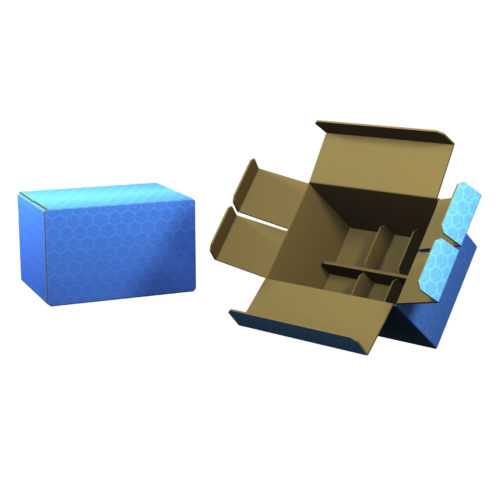

This Shipping Box With A Built-In Multi-Divider is a great tool to keep your products organized and safe during shipping. Thanks to the multiple dividers in the construction, your can have multiple product types segmented inside the box. Or you could create a great presentation inside using the different open areas between the dividers.

This Shipping Box With A Built-In Multi-Divider is a great tool to keep your products organized and safe during shipping. Thanks to the multiple dividers in the construction, your can have multiple product types segmented inside the box. Or you could create a great presentation inside using the different open areas between the dividers. -

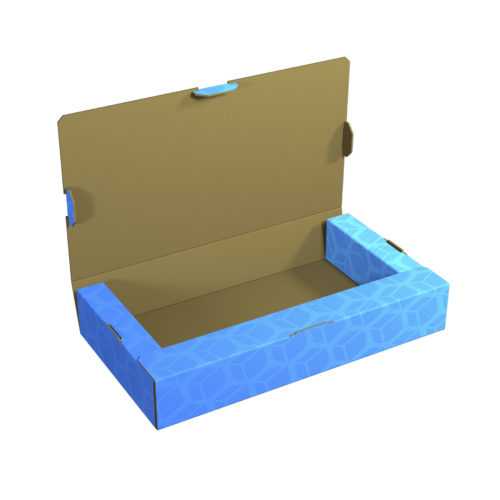

The Five Panel Folder (5PF) is ideal for transporting lengthy, heavy, or irregularly shaped products. 5PFs, which consists of a single corrugated sheet that has been sliced and scored, has a fifth panel that acts as a closing flap and entirely encloses a side panel. This makes loading products during fulfillment simple; all that is needed is to wrap the box over the item and tape it shut. A side panel is entirely covered by a fifth panel that serves as the closing flap on a single cut and scored piece. In order to provide stacking strength and safety for long objects with tiny diameter that may be harmed or damage the box if pushed through the ends, the closed box contains many layers of combined board on each end.

The Five Panel Folder (5PF) is ideal for transporting lengthy, heavy, or irregularly shaped products. 5PFs, which consists of a single corrugated sheet that has been sliced and scored, has a fifth panel that acts as a closing flap and entirely encloses a side panel. This makes loading products during fulfillment simple; all that is needed is to wrap the box over the item and tape it shut. A side panel is entirely covered by a fifth panel that serves as the closing flap on a single cut and scored piece. In order to provide stacking strength and safety for long objects with tiny diameter that may be harmed or damage the box if pushed through the ends, the closed box contains many layers of combined board on each end. -

The Full Overlap (FOL) box is designed to handle big loads. When folded, the flaps on this design fully encircle one another and reach across both sides of your product in order for it be stored or delivered with full integrity- which makes them perfect if you need a sturdy storage solution! The robustness means they can withstand fulfillment processes without any issues whatsoever; however during transport these are not meant as packaging so care must still applied when handling them accordingly (i e: don't scuff).

The Full Overlap (FOL) box is designed to handle big loads. When folded, the flaps on this design fully encircle one another and reach across both sides of your product in order for it be stored or delivered with full integrity- which makes them perfect if you need a sturdy storage solution! The robustness means they can withstand fulfillment processes without any issues whatsoever; however during transport these are not meant as packaging so care must still applied when handling them accordingly (i e: don't scuff). -

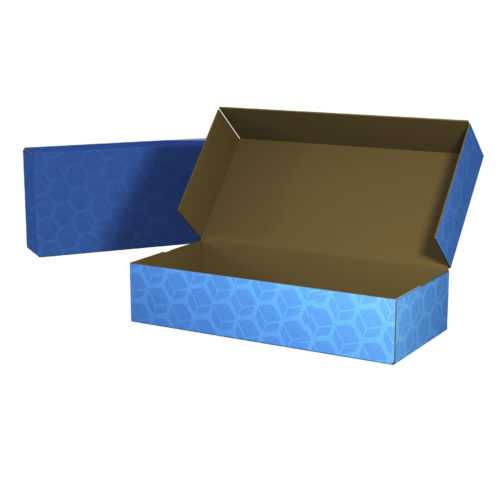

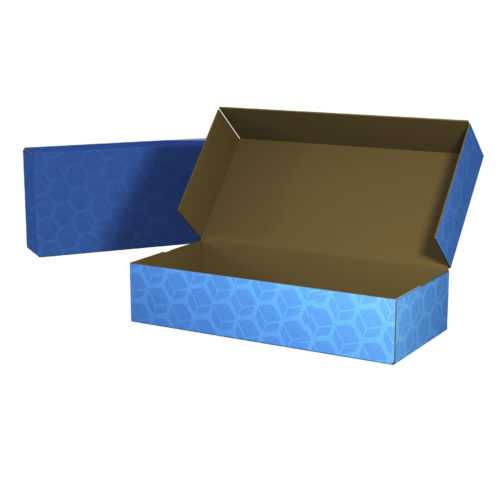

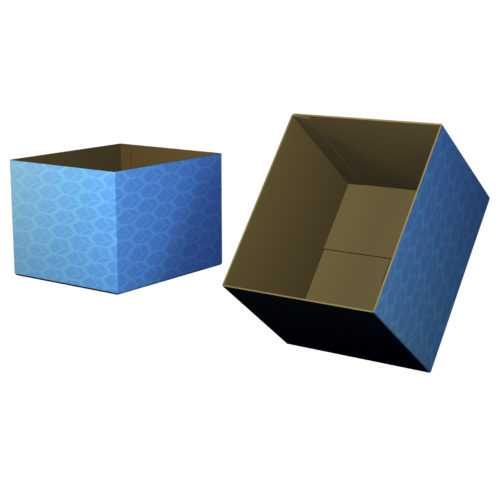

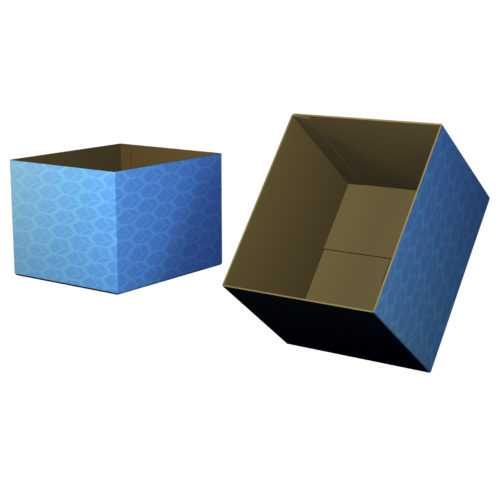

The Half Slotted Container (HSC) offers a wide range of uses for storing and transporting and is effective, resilient, and extremely adaptable. When the box is folded, bottom flaps of equal length meet in the middle, but top flaps are missing, leaving the top of the box exposed. HSC's are frequently used as storage bins, rapid transit containers within production facilities, or in conjunction with Design Style Trays to serve as covered boxes. Although similar to regular slotted containers, a half slotted box has only one set of flaps and leaves the top uncovered.

The Half Slotted Container (HSC) offers a wide range of uses for storing and transporting and is effective, resilient, and extremely adaptable. When the box is folded, bottom flaps of equal length meet in the middle, but top flaps are missing, leaving the top of the box exposed. HSC's are frequently used as storage bins, rapid transit containers within production facilities, or in conjunction with Design Style Trays to serve as covered boxes. Although similar to regular slotted containers, a half slotted box has only one set of flaps and leaves the top uncovered. -

With an easy-to-click in self-locking tab, the Self-Locking One Piece Folder has all the advantages of the conventional OPF without using tape to attach it. Customers may enjoy a beautiful unpacking presentation using this design, which also lets you arrange the contents however you see fit. The self locking tabs make sure nothing gets mixed up during shipment, while also ensuring they stay in place until needed!

With an easy-to-click in self-locking tab, the Self-Locking One Piece Folder has all the advantages of the conventional OPF without using tape to attach it. Customers may enjoy a beautiful unpacking presentation using this design, which also lets you arrange the contents however you see fit. The self locking tabs make sure nothing gets mixed up during shipment, while also ensuring they stay in place until needed! -

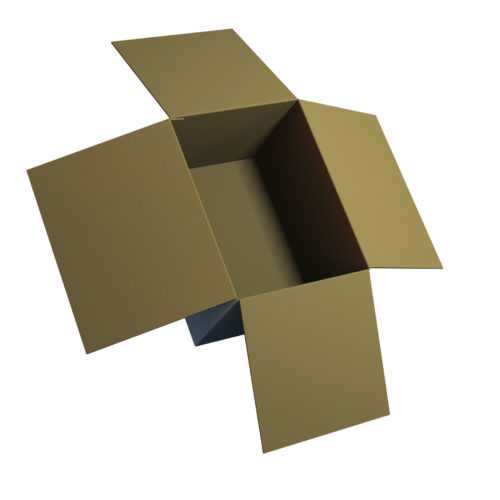

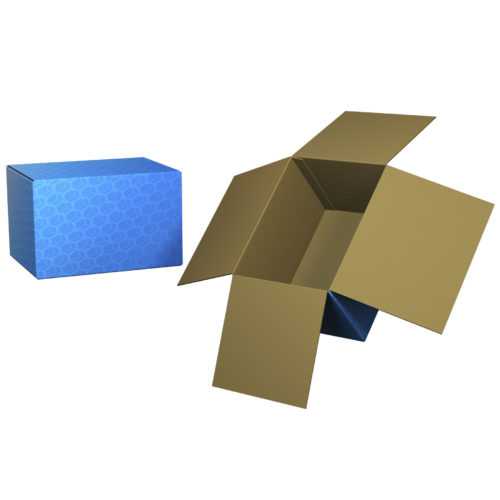

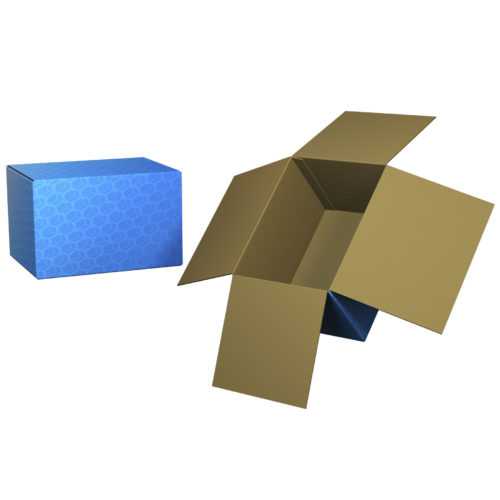

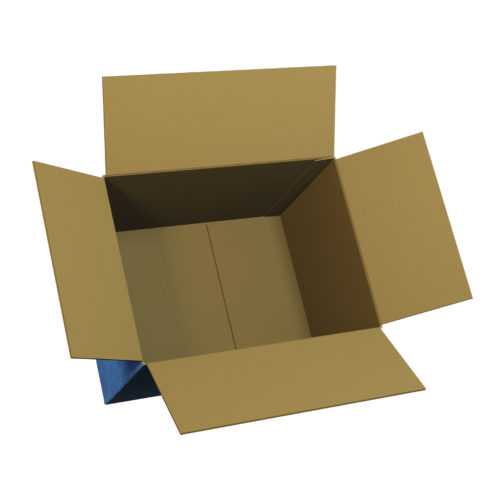

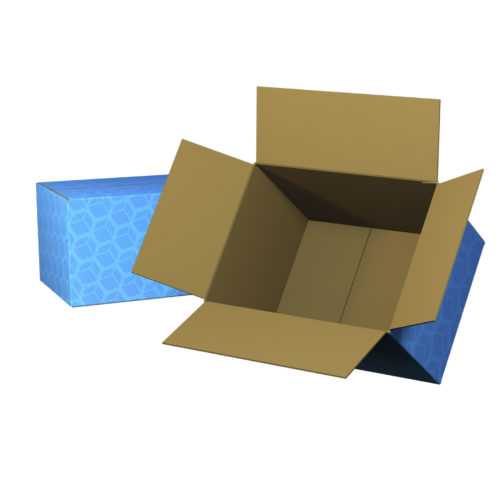

The Regular Slotted Container (RSC) is the most common box style in the world because of it's almost perfect design. Thanks to the minmimal amount of cuts and folds, and single-piece construction, it's a very cost-effective option. This style is great at minimizing waste, and maximizing structural integrity. Keep your products organized and safe inside during shipping with this great design.

The Regular Slotted Container (RSC) is the most common box style in the world because of it's almost perfect design. Thanks to the minmimal amount of cuts and folds, and single-piece construction, it's a very cost-effective option. This style is great at minimizing waste, and maximizing structural integrity. Keep your products organized and safe inside during shipping with this great design. -

The Regular Slotted Container (RSC) Auto Bottom resembles a regular RSC, but has a pre-glued bottom. The Auto Bottom design offers a fast assembly and quicker loading during fulfillment while saving money over time on labor and tape costs. Auto-lock (auto-bottom) boxes are designed for quick assembly. Pre-gluing eliminates the requirement to first tape the self-assembling bottom before turning it right-side up to insert merchandise. It's as simple as opening the box, adding the contents, and shutting it (either with tape or a convenient tuck top).

The Regular Slotted Container (RSC) Auto Bottom resembles a regular RSC, but has a pre-glued bottom. The Auto Bottom design offers a fast assembly and quicker loading during fulfillment while saving money over time on labor and tape costs. Auto-lock (auto-bottom) boxes are designed for quick assembly. Pre-gluing eliminates the requirement to first tape the self-assembling bottom before turning it right-side up to insert merchandise. It's as simple as opening the box, adding the contents, and shutting it (either with tape or a convenient tuck top). -

By streamlining assembly and lowering the cost of labor and tape over time, the Regular Slotted Container Snap Lock Bottom (RSC) box helps businesses save money. The bottom flaps fold to produce a secured lock, keeping it closed without the use of glue, tape, or staples. The regular flaps meet in the middle at the top. This design is ideal for large and lightweight products. The 1-2-3 bottom box, also known as the snap-lock bottom box, is a type of folding bottom box that is quite common in the packaging sector. The process of folding it is quick, and it holds large objects very well. For a secure closure, the bottom flaps are connected with one another.

By streamlining assembly and lowering the cost of labor and tape over time, the Regular Slotted Container Snap Lock Bottom (RSC) box helps businesses save money. The bottom flaps fold to produce a secured lock, keeping it closed without the use of glue, tape, or staples. The regular flaps meet in the middle at the top. This design is ideal for large and lightweight products. The 1-2-3 bottom box, also known as the snap-lock bottom box, is a type of folding bottom box that is quite common in the packaging sector. The process of folding it is quick, and it holds large objects very well. For a secure closure, the bottom flaps are connected with one another. -

The Tuck Top Auto Lock Bottom is a great choice for fast assembly. Four flaps that fold and lock together to form the bottom are present. Compared to the Tuck Top Auto Bottom, this design is more affordable, but it takes longer to assemble. It is perfect for heavier objects because of the sturdy design and bottom snap closing. Pre-gluing eliminates the requirement to first tape the self-assembling bottom before turning it right-side up to insert merchandise. It's as simple as opening the box, adding the contents, and shutting it (either with tape or a convenient tuck top).

The Tuck Top Auto Lock Bottom is a great choice for fast assembly. Four flaps that fold and lock together to form the bottom are present. Compared to the Tuck Top Auto Bottom, this design is more affordable, but it takes longer to assemble. It is perfect for heavier objects because of the sturdy design and bottom snap closing. Pre-gluing eliminates the requirement to first tape the self-assembling bottom before turning it right-side up to insert merchandise. It's as simple as opening the box, adding the contents, and shutting it (either with tape or a convenient tuck top). -

The Tuck top Snap Lock Bottom is an economical box designed to store heavier products, and more. Four flaps that fold and lock together to form the bottom are present. Compared to the Tuck Top Auto Bottom, this design is more affordable, but it takes longer to assemble. It is perfect for heavier objects because of the sturdy design and bottom snap closing. The 1-2-3 bottom box, also known as the snap-lock bottom box, is a type of folding bottom box that is quite common in the packaging sector. The process of folding it is quick, and it holds large objects very well. For a secure closure, the bottom flaps are connected with one another.

The Tuck top Snap Lock Bottom is an economical box designed to store heavier products, and more. Four flaps that fold and lock together to form the bottom are present. Compared to the Tuck Top Auto Bottom, this design is more affordable, but it takes longer to assemble. It is perfect for heavier objects because of the sturdy design and bottom snap closing. The 1-2-3 bottom box, also known as the snap-lock bottom box, is a type of folding bottom box that is quite common in the packaging sector. The process of folding it is quick, and it holds large objects very well. For a secure closure, the bottom flaps are connected with one another.

Skip to content